In today’s fast-paced world, ensuring the reliability of equipment and systems is paramount for success. A systematic approach to overseeing assets not only prolongs their lifespan but also minimizes unexpected disruptions. By adopting a proactive strategy, organizations can safeguard their investments and enhance operational efficiency.

A well-organized framework for scheduling essential checks and services empowers teams to stay ahead of potential issues. By anticipating needs and addressing them before they escalate, businesses can create a culture of preparedness and resilience. This methodical practice fosters an environment where productivity thrives, reducing downtime and extending the useful life of critical resources.

Implementing a structured timeline for evaluations and interventions requires thoughtful planning and consistent execution. Organizations that embrace this principle will benefit from improved performance and cost savings over time. Moreover, such a strategy not only enhances reliability but also instills confidence in stakeholders, reinforcing a commitment to excellence and sustainability.

Importance of Preventive Maintenance

Ensuring the longevity and efficiency of equipment is vital for any organization. Proactive care not only enhances performance but also minimizes unexpected breakdowns. By anticipating issues and addressing them before they escalate, businesses can save time and resources while maintaining smooth operations.

Cost-Effectiveness

Implementing a strategy focused on regular check-ups can lead to significant savings in the long run. By catching minor problems early, companies avoid costly repairs and replacements. Additionally, equipment that is well-cared for tends to have a longer lifespan, providing greater return on investment.

Enhanced Safety and Compliance

Regular inspections contribute to a safer working environment. Equipment that is routinely checked is less likely to malfunction, reducing the risk of accidents. Furthermore, adhering to industry standards and regulations is essential, and consistent upkeep helps ensure compliance, protecting both employees and the organization from potential liabilities.

Key Benefits of Regular Maintenance

Consistent attention to equipment and systems can yield numerous advantages that enhance operational efficiency and prolong lifespan. By committing to routine check-ups and servicing, organizations can prevent minor issues from escalating into major problems, ensuring a smoother and more reliable operation.

Improved Reliability

- Routine inspections help identify wear and tear early, reducing the likelihood of unexpected breakdowns.

- Well-maintained equipment performs better, resulting in fewer disruptions during operations.

- Regular servicing builds trust in the equipment’s reliability among employees and management.

Cost Savings

- Addressing small issues promptly can save significant costs associated with major repairs.

- Efficient operations reduce energy consumption, leading to lower utility bills.

- Extended equipment lifespan minimizes the frequency of costly replacements.

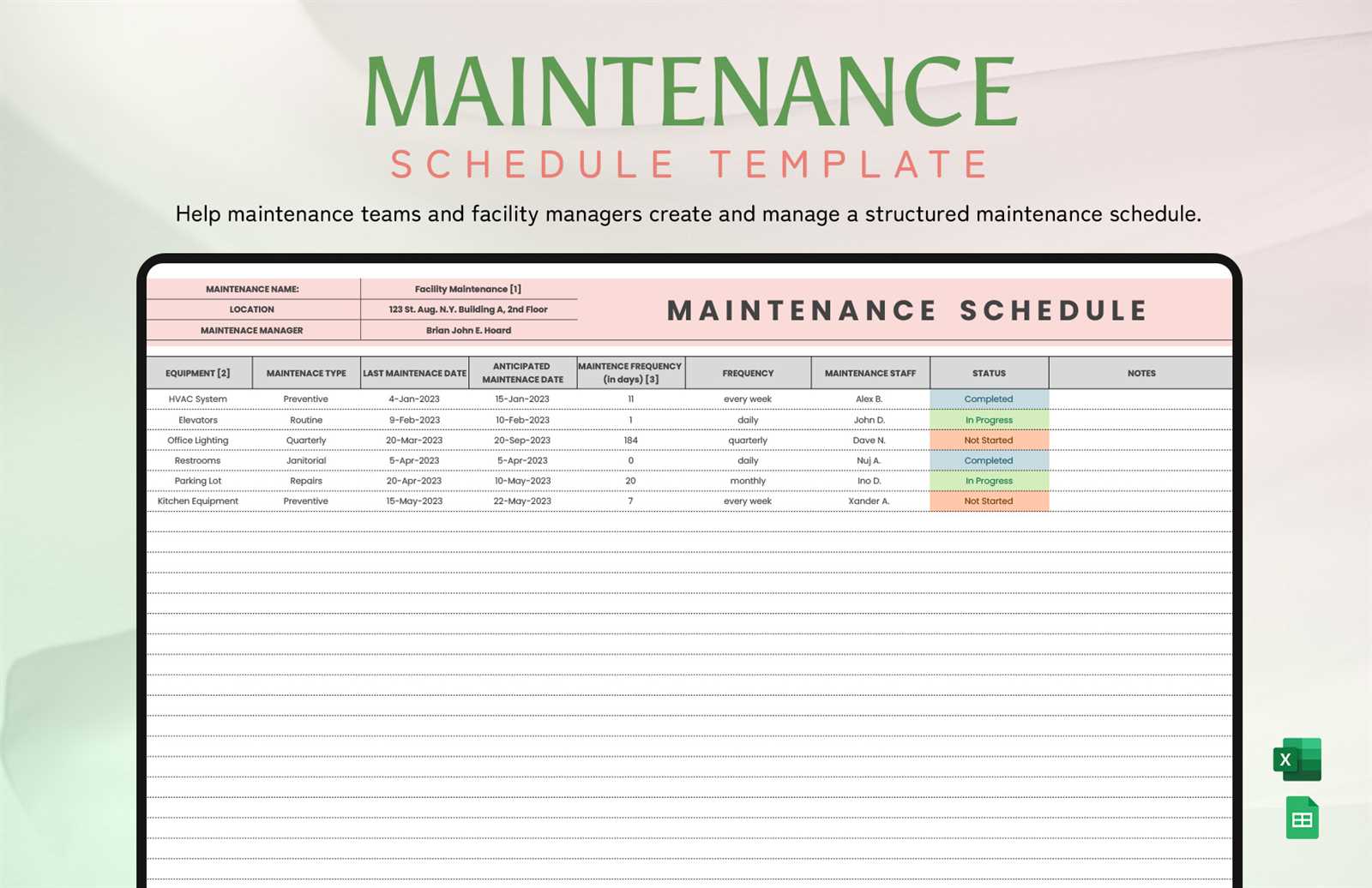

Understanding Maintenance Calendars

Effective planning is crucial for ensuring the longevity and reliability of equipment. By organizing tasks and activities systematically, organizations can anticipate needs, allocate resources efficiently, and minimize unexpected disruptions. A well-structured approach to scheduling can significantly enhance operational performance.

Importance of Structured Scheduling

Having a systematic framework allows teams to track their obligations and deadlines effectively. This organized methodology ensures that essential tasks are completed timely, reducing the risk of breakdowns and optimizing productivity. Regularly revisiting this framework can help identify areas for improvement and adaptation to changing conditions.

Key Elements to Consider

When developing a scheduling framework, it is vital to identify critical tasks and prioritize them based on urgency and frequency. Additionally, incorporating feedback from team members can lead to a more comprehensive understanding of requirements. Utilizing digital tools can also facilitate easier tracking and adjustments, making the overall process more efficient and less prone to errors.

Types of Maintenance Strategies

In the realm of asset upkeep, various approaches can be employed to ensure optimal performance and longevity. Each method has its unique characteristics, suited to different operational needs and environments. Understanding these strategies allows organizations to tailor their efforts for maximum efficiency and cost-effectiveness.

Reactive Approaches

This strategy revolves around addressing issues as they arise. Often viewed as a firefighting method, it can lead to unexpected downtimes and potentially costly repairs. While this technique can be effective in certain contexts, it often results in a reactive cycle that can strain resources over time.

Proactive Techniques

In contrast, proactive measures focus on anticipating potential problems before they occur. This strategy emphasizes regular inspections and condition monitoring, enabling teams to take action based on the current state of equipment. By implementing these forward-thinking practices, organizations can enhance reliability and significantly reduce the likelihood of sudden failures.

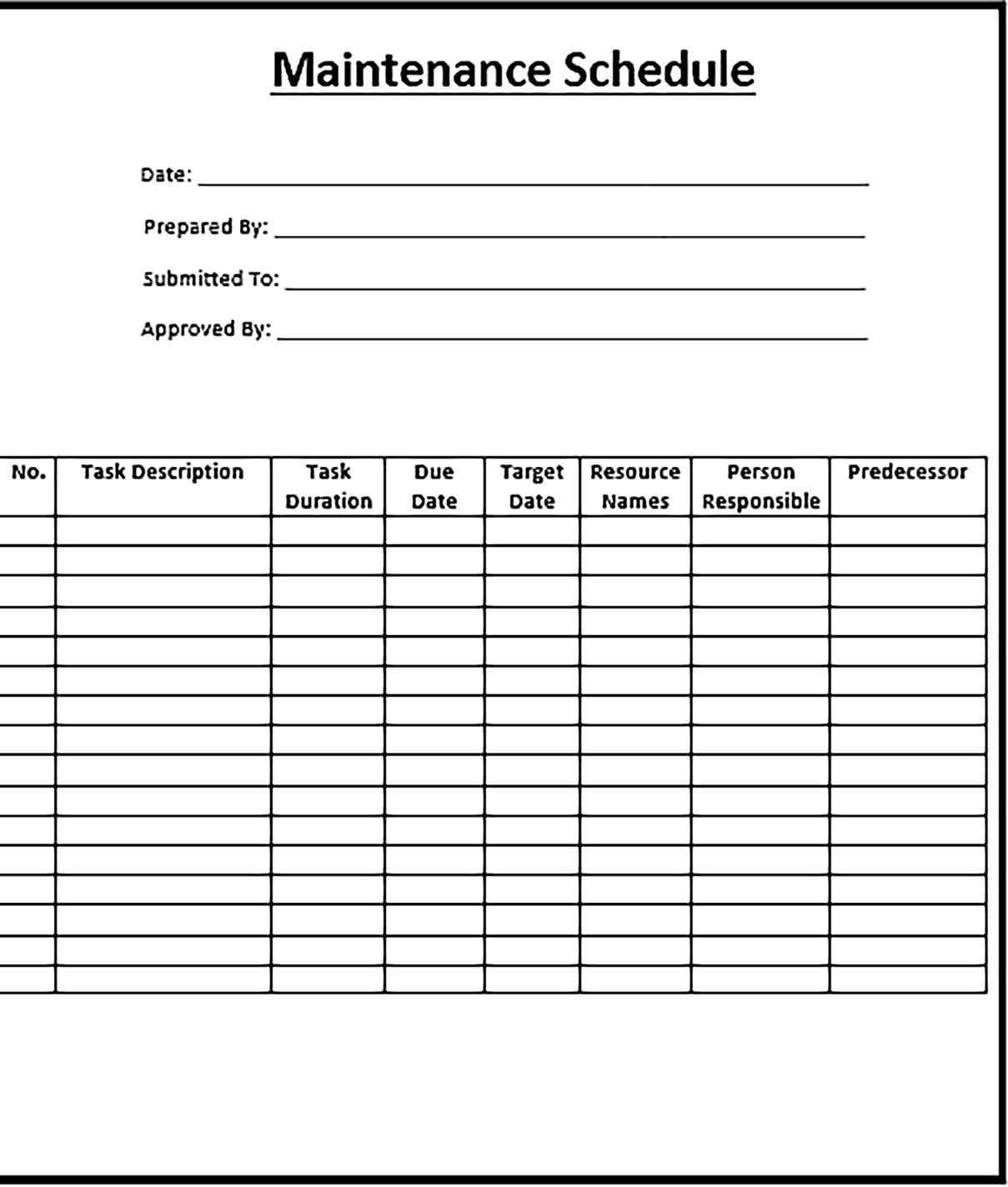

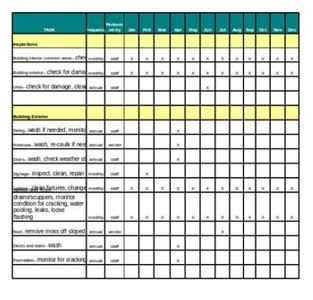

Creating a Maintenance Schedule

Establishing a systematic plan for regular check-ups and services is essential for ensuring the longevity and efficiency of equipment and facilities. A well-structured approach helps identify tasks that require attention and allows for timely interventions, minimizing unexpected failures and costly repairs.

Identifying Key Tasks

Start by listing all essential operations that need regular attention. This can include inspections, cleaning, and replacements of parts. Collaborate with team members to ensure no critical tasks are overlooked. Prioritize these tasks based on their importance and frequency of occurrence.

Setting Frequency and Timing

Determine how often each task should be performed. Consider factors such as usage patterns and manufacturer recommendations. By assigning specific time frames–whether weekly, monthly, or quarterly–you can create a realistic plan that aligns with operational demands. Documenting these intervals in a clear format helps keep the process organized and accessible.

Incorporating these elements into your scheduling will foster a proactive approach, ultimately enhancing the reliability of your systems.

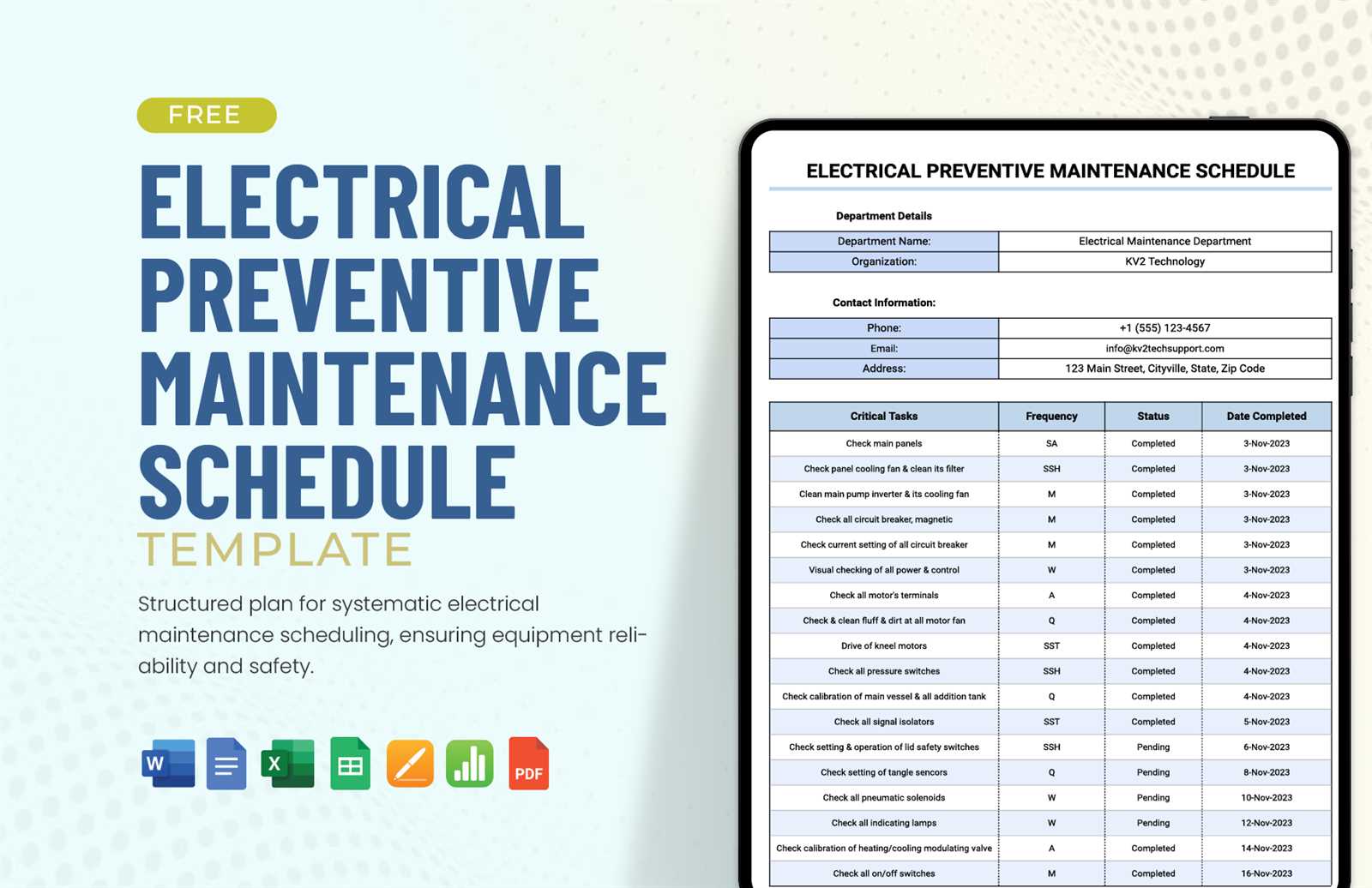

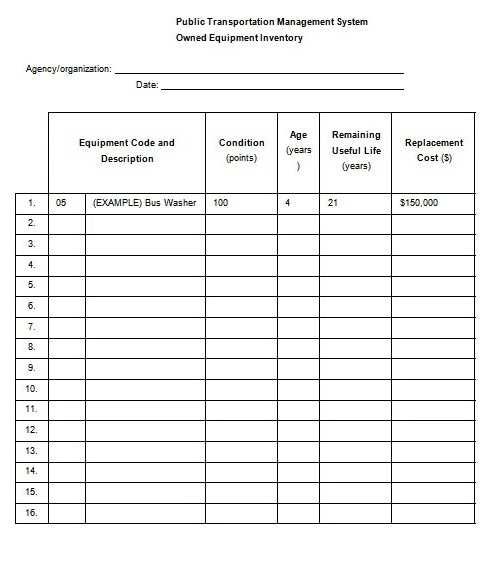

Essential Elements of a Template

Creating a structured outline for scheduling and organization involves several key components that ensure efficiency and clarity. These elements serve as the foundation for developing a reliable framework, enabling users to streamline their processes effectively.

Here are the critical components that should be included:

| Element | Description |

|---|---|

| Title | A clear and concise heading that indicates the purpose of the document. |

| Frequency | Specifies how often tasks need to be addressed, whether daily, weekly, or monthly. |

| Task List | A detailed enumeration of tasks or activities that require attention. |

| Responsibility | Assigns specific individuals or teams to each task, ensuring accountability. |

| Due Dates | Indicates deadlines for each task, facilitating timely completion. |

| Notes | Provides space for additional comments or instructions related to each task. |

Incorporating these elements will enhance the usability of the document, leading to improved organization and effectiveness in achieving set objectives.

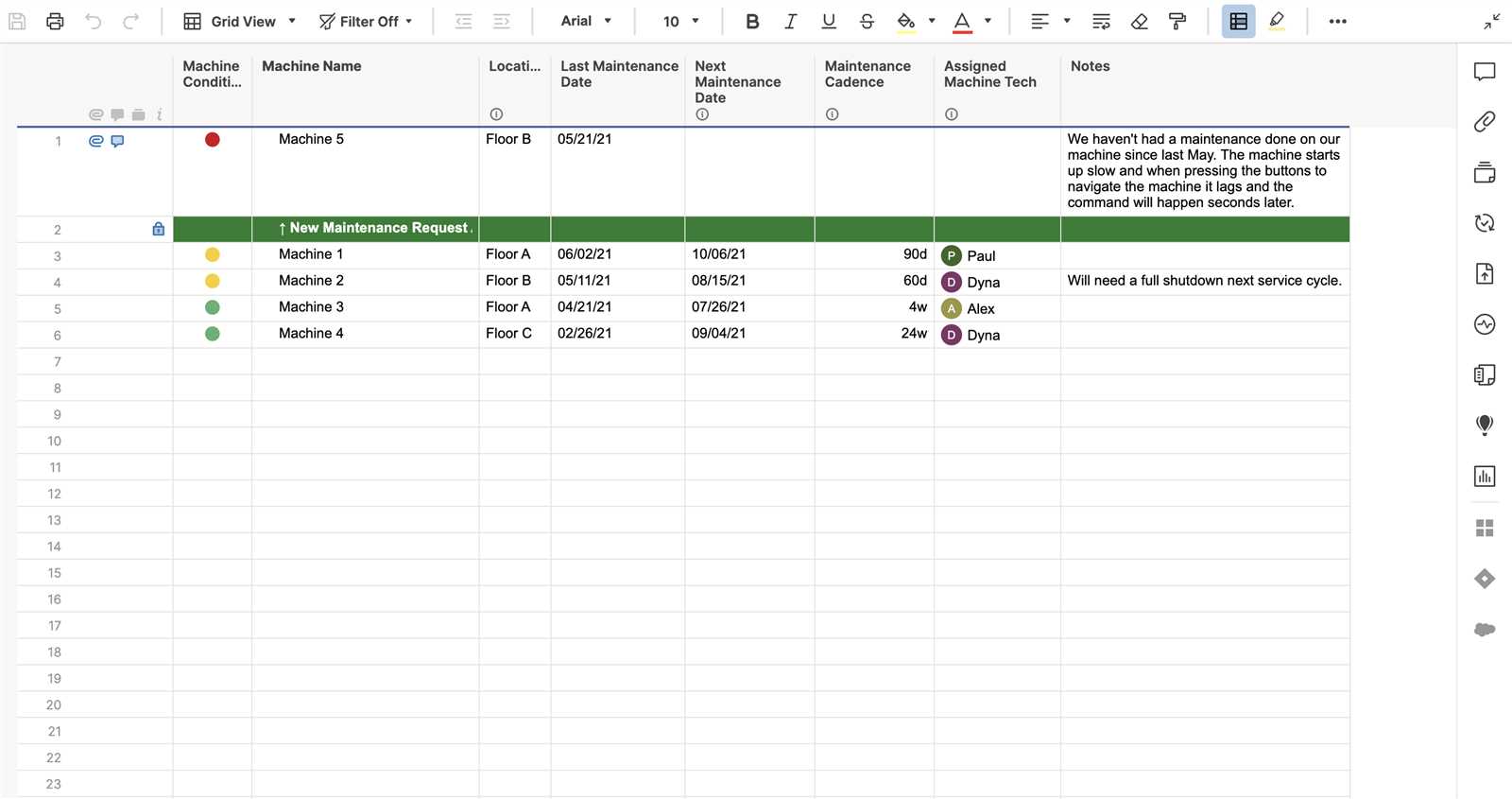

Tools for Maintenance Management

Effective management of upkeep processes is crucial for ensuring that equipment operates smoothly and efficiently. Various resources are available to assist in organizing tasks, tracking performance, and improving overall operational reliability. Utilizing the right tools can lead to significant enhancements in productivity and cost savings, helping teams stay ahead of potential issues before they escalate.

Software Solutions

Modern software applications provide robust functionalities that streamline operations. These platforms often include features such as task scheduling, asset tracking, and reporting tools. By centralizing data, teams can make informed decisions, allocate resources wisely, and analyze performance metrics over time, leading to more efficient workflows.

Mobile Applications

Mobile technology has revolutionized how teams approach their responsibilities on-site. Dedicated applications enable instant access to information, allowing personnel to log activities, receive alerts, and communicate effectively while on the go. This flexibility ensures that teams can respond promptly to emerging challenges, ultimately enhancing the reliability of equipment and systems.

How to Customize Your Template

Tailoring your organizational plan can significantly enhance its effectiveness. Personalization allows you to align the framework with your specific needs and preferences, ensuring optimal utility and engagement.

Here are some key strategies for making your framework truly yours:

- Identify Your Objectives: Clearly define what you aim to achieve. This clarity will guide your customization efforts.

- Select Relevant Tasks: Choose the activities that are most pertinent to your goals. Focus on those that will drive results.

- Adjust Timeframes: Modify the frequency and duration of tasks to match your workflow. Flexibility is essential for success.

- Add Visual Elements: Incorporate colors, icons, or images that resonate with you. Visual cues can enhance motivation and engagement.

- Integrate Technology: Utilize software tools or applications that streamline tracking and reminders. Automation can save time and effort.

By implementing these adjustments, you can create a dynamic and personalized approach that meets your unique requirements and fosters productivity.

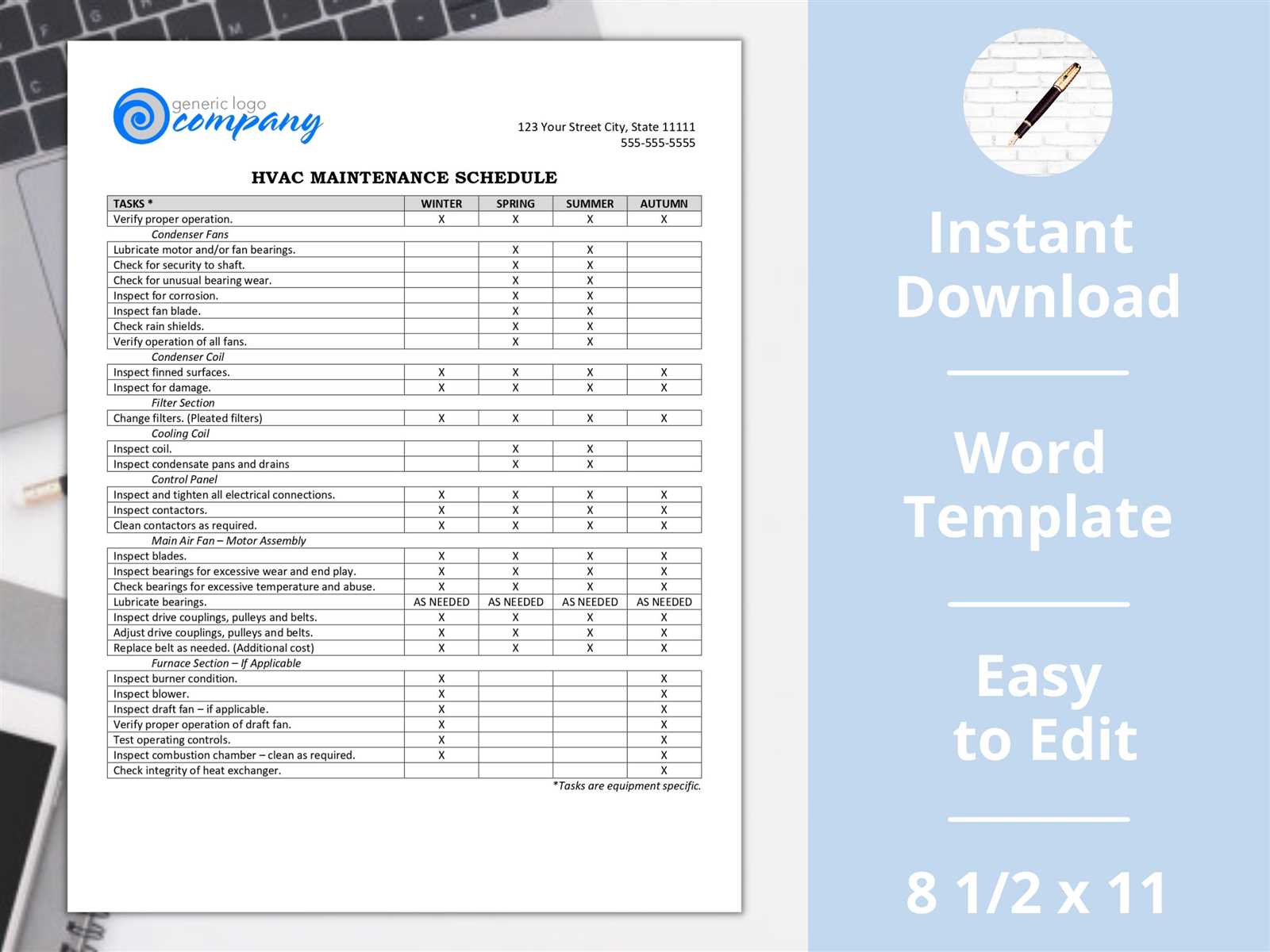

Common Maintenance Tasks to Include

In any organization, it’s essential to have a structured approach to routine care of equipment and facilities. Incorporating a variety of specific actions ensures that everything operates smoothly and efficiently over time. Below are key tasks that should be regularly addressed to prolong the lifespan of assets and enhance operational reliability.

- Checking and replacing filters in HVAC systems to improve air quality and system efficiency.

- Lubricating moving parts of machinery to reduce wear and tear and prevent breakdowns.

- Inspecting electrical systems for any signs of wear, loose connections, or potential hazards.

- Cleaning and clearing drainage systems to prevent blockages and flooding.

- Examining safety equipment, such as fire extinguishers and alarms, to ensure they are functional.

Each of these tasks contributes to a proactive strategy aimed at minimizing unexpected failures and extending the useful life of assets. Regular reviews and updates to the list can help in adapting to the specific needs of the organization.

- Performing routine software updates to keep systems secure and efficient.

- Conducting inventory checks on tools and equipment to identify necessary replacements.

- Reviewing and testing emergency procedures to ensure readiness in case of incidents.

By integrating these essential tasks into a systematic approach, organizations can significantly enhance their operational performance and reliability.

Setting Up Maintenance Reminders

Creating a systematic approach to remind yourself of essential tasks can significantly enhance the longevity and efficiency of your equipment. By establishing regular notifications, you can ensure that nothing is overlooked, allowing you to maintain optimal performance and avoid unexpected issues.

Choosing the Right Frequency

Determining how often to receive alerts is crucial. Consider the usage patterns and requirements of each item. For instance, machinery used daily may necessitate more frequent check-ins, while seasonal equipment could benefit from reminders spaced further apart. A thoughtful schedule not only keeps you organized but also aligns with your operational needs.

Utilizing Digital Tools

Incorporating technology can streamline your reminder system. Various applications and software are designed to assist in tracking tasks. Look for features such as automatic notifications, customizable timelines, and reporting tools. These resources can simplify the process, making it easier to stay on top of essential activities without overwhelming your workflow.

In conclusion, establishing a robust reminder system is an investment in the reliability and performance of your assets. By choosing appropriate intervals and leveraging digital solutions, you can effectively safeguard your equipment and ensure its readiness for use.

Integrating Technology in Maintenance

Embracing modern technology can significantly enhance the efficiency and effectiveness of upkeep processes. By leveraging innovative tools and systems, organizations can streamline operations, reduce costs, and improve overall performance. This integration not only aids in monitoring and analyzing equipment conditions but also facilitates timely interventions, ensuring that systems operate at peak performance.

Benefits of Technological Integration

Utilizing advanced technology brings numerous advantages to upkeep strategies. It allows for real-time data collection, predictive analysis, and automated alerts, which can lead to more informed decision-making. Furthermore, digital platforms can simplify communication among team members, ensuring everyone is aligned and informed.

Technological Tools to Consider

| Tool | Description | Benefits |

|---|---|---|

| IoT Sensors | Devices that monitor equipment conditions remotely. | Real-time data and proactive issue detection. |

| CMMS Software | Computerized systems for managing upkeep tasks. | Improved organization and task tracking. |

| Predictive Analytics | Tools that forecast potential equipment failures. | Reduced downtime and optimized resource allocation. |

Integrating these technologies fosters a proactive approach, enabling organizations to address issues before they escalate. This not only preserves assets but also contributes to a more sustainable operational model.

Tracking Maintenance Performance Metrics

Monitoring the effectiveness of upkeep activities is crucial for optimizing operations and ensuring the longevity of assets. By analyzing various performance indicators, organizations can identify trends, pinpoint issues, and implement improvements that lead to increased reliability and efficiency.

Key Performance Indicators (KPIs)

Establishing a set of KPIs allows teams to evaluate their efforts systematically. Consider the following indicators:

- Downtime: Measure the total time equipment is out of service due to repairs.

- Cost Efficiency: Assess the total expenditure related to upkeep activities versus the budget allocated.

- Task Completion Rate: Track the percentage of scheduled tasks that are completed on time.

- Asset Availability: Monitor the proportion of time equipment is operational and available for use.

Benefits of Tracking Metrics

Implementing a robust tracking system offers numerous advantages:

- Enhances decision-making by providing data-driven insights.

- Promotes proactive strategies to address potential problems before they escalate.

- Facilitates communication among teams through shared performance data.

- Supports continuous improvement initiatives, fostering a culture of excellence.

In conclusion, effectively tracking performance metrics is essential for refining upkeep strategies, ensuring resources are utilized wisely, and achieving organizational goals. By focusing on relevant indicators, teams can drive significant enhancements in their operational practices.

Reviewing and Updating Your Calendar

Regularly assessing and revising your scheduling framework is crucial for ensuring its effectiveness and relevance. This process not only helps identify areas for improvement but also allows you to adapt to changing circumstances and needs. By prioritizing a thorough evaluation, you can enhance overall productivity and reduce the likelihood of oversights.

Identifying Areas for Improvement

Begin by analyzing the current structure and content of your scheduling system. Look for any inconsistencies or gaps that may hinder efficiency. Gathering feedback from team members can provide valuable insights, highlighting aspects that may require adjustments. Documenting these observations will serve as a foundation for making informed updates.

Implementing Changes

Once you have identified necessary modifications, outline a clear plan for implementation. This may involve revising timelines, adjusting frequency, or integrating new tools to enhance organization. Regularly updating your framework ensures it remains aligned with your objectives and optimally supports your operational goals. By committing to this continuous improvement process, you foster a more responsive and efficient environment.

Training Staff on Maintenance Procedures

Effective instruction of personnel in operational protocols is essential for ensuring equipment longevity and efficiency. A well-structured training program empowers team members with the knowledge needed to identify issues before they escalate, thereby fostering a proactive approach to equipment care.

Importance of Comprehensive Training

Providing thorough education helps staff understand the intricacies of machinery and systems they work with daily. When employees are well-versed in standard operating procedures, they are more likely to recognize potential problems and address them promptly. This knowledge not only enhances their confidence but also significantly reduces the risk of costly breakdowns.

Implementing Training Sessions

Organizing regular training workshops can be beneficial for all team members. Utilizing hands-on demonstrations and interactive sessions encourages engagement and retention of information. Incorporating simulations allows staff to practice responses to various scenarios, reinforcing their understanding and readiness. Additionally, providing access to detailed manuals and resources can serve as ongoing references, ensuring that employees remain informed about best practices.

By investing in staff education, organizations can cultivate a culture of responsibility and vigilance, ultimately leading to improved operational efficiency.

Case Studies of Successful Implementations

This section explores various instances where proactive strategies have been effectively integrated into operational frameworks. By examining real-world applications, we can identify key elements that contribute to successful outcomes, showcasing the benefits of systematic approaches in different industries.

One notable example comes from a manufacturing facility that adopted a structured approach to equipment oversight. By scheduling regular inspections and adjustments, they significantly reduced unexpected downtimes, which in turn enhanced productivity levels and overall output. The implementation process involved thorough training sessions for staff, ensuring everyone understood the importance of their roles in the initiative.

In another case, a transportation company revamped its approach to vehicle care by incorporating routine checks and services into its operational practices. This shift led to improved reliability and safety on the roads. By analyzing data from these procedures, the company was able to fine-tune its processes, ultimately resulting in lower operational costs and increased customer satisfaction.

Additionally, a healthcare facility that integrated a systematic approach to equipment oversight witnessed remarkable improvements in service delivery. By regularly assessing and updating their medical devices, they ensured optimal functionality, which directly contributed to better patient outcomes. The staff’s engagement in this initiative fostered a culture of accountability and continuous improvement.

These case studies illustrate how implementing organized strategies can yield significant advantages across various sectors. Through careful planning and execution, organizations can achieve greater efficiency and enhance their service quality, paving the way for long-term success.

Potential Challenges and Solutions

In the realm of equipment upkeep, various obstacles can impede efficiency and effectiveness. Identifying these hurdles is crucial for implementing strategies that ensure optimal performance and longevity of assets.

Common Obstacles

One major challenge is the lack of resources, including time and personnel, which can lead to incomplete tasks. Additionally, insufficient training can result in improper execution of procedures, ultimately increasing the risk of failures.

Effective Strategies

To address these issues, organizations can prioritize resource allocation, ensuring that sufficient time and staff are designated for tasks. Furthermore, investing in comprehensive training programs can empower teams, enhancing their skills and confidence in handling equipment properly.